They can stamp your emblem or messages, produce unique colors and patterns and package them particularly predicated on what you want and need.

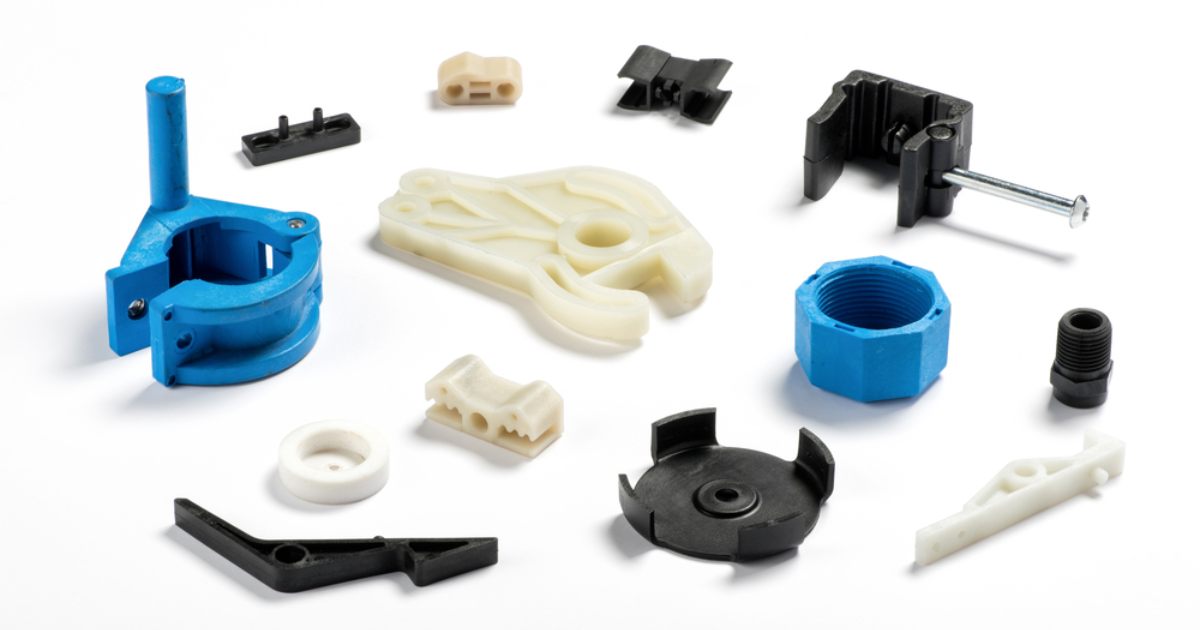

Most of the custom treatment molding organizations may make any plastic product you specify, however not them all move the excess distance to look after’concluding solutions’such as decorating, assembly, marking and packaging. Some have even a design group that could aid clients with plastic portion and form design. From quick prototyping and tooling to shot molding, ultrasonic and plastic welding and creating, these businesses may aid you every stage of the way. Select makers that provide these included rewards – you can become keeping time, income and effort.

Note that some custom injection molding companies don’t do these accessories in-house – they hire sub-assemblers and finishers, but are still ready to create products at par with your standards. Also study the manufacturing company’s logistics and scheduling system. They should manage to manage your supply wants regardless of how challenging they could be. You should also choose companies that apply strict controls to monitor the entire custom procedure molding process. They ought to have the newest examination gear at hand to allow them to complement the closest tolerance and ergo offer quality consistently.

The injection mold manufacturers company’s seed climate can also be very important. They ought to have facilities that assure mold cooling system control. You may contact any organizations in the web listing for your custom procedure molding needs. If your business has particular parts so it employs within its completed products and services, it’s probably depended on the services of an agreement custom injection mold producer to provide specific plastic areas or modules. In some instances, these measures are lucrative for producer while giving your organization with precision engineered components that match your large standards.

Often, however, you have to stop the contract since the fabrication business proves to be unreliable. Late deliveries, missed deadlines, sub-par quality or even unfortunate problems at the seed may all keep your own company in the lurch if producer can not or won’t make excellent on its promises. When you have to shop about for a fresh custom injection mold producer, you will find five features you ought to search for:

As you probably have your own designers, it’s generally better to utilize a contract production company that has their very own in-house designers who can assist you to produce or increase a prototype for every single element you need. These specialists may recommend substitute methods of manufacture and present style help so that you get with a high quality solution every time. They’re also invaluable as trouble-shooters in case there is a problem during manufacture, reducing down time and ensuring your generation run will not be delayed any more than absolutely necessary.

Perhaps your organization wants an injection shaped element for your overall challenge, but can exactly the same maker that’s presently providing these areas also generate the thermoset materials or structural foam pieces you will need next season? While you could work with five different vendors below five various contracts, it’s easier and less expensive to obtain as many plastic parts made by the same business as possible.

In a perfect world, you will never desire a speed work or need extra shifts to generally meet item need, but this isn’t a great world. Your custom shot mold contractor must be able to typically work three whole changes in the event that you will need a rush work or have an unforeseen number of purchases to fill. If your present produce runs only 1 shift, what’ll they be able to do for you when you need more parts in less time?

Thermoplastics manufacturing isn’t an business noted for their outstanding customer care help, but that doesn’t suggest you have to put up with unanswered telephone calls, missing communications or any other distractions that may decrease creation and build issues through misunderstandings. When you signal an agreement with your new custom treatment form supplier, contact their customer support department. Did they answer the telephone in a regular way? Were they able to solution your issues or direct one to the right individual to obtain a solution? Were they personable and nice?